FOOD SAFETY

FOOD SAFETY

SS 590:2013 HACCP – based Food Safety Management System

SS 590:2013 HACCP – based Food Safety Management System

Food safety and hygiene is the utmost vital criteria within the food supply chain as it protects the health of consumers from having food borne illness and food poisoning.

Singapore enjoys one of the lowest rates of food borne diseases outbreaks compare to the rest of the world even most of the food is being imported to the country. This is because Singapore practices stringent food safety standards with Singapore Food Agency (SFA) put in place an effective integrated food safety system to ensure food is safe for consumption.

The assurance of food safety needs collaboration efforts from the industry as well as the consumers in Singapore as no system is foolproof since food safety is a shared responsibility.

What is SS 590 certification?

SS 590:2013 is a standard prepared by the Technical Committee under the direction of the Food Standards Committee, which specifies requirements for a HACCP-based food safety management system (FSMS). This standard was published to replace SAC HACCP Document No. 2 – Management of food safety based on HACCP (Hazard Analysis and Critical Control Point) – Requirements for a HACCP-based food management system, for use by food organisations, particularly by small and medium-sized food organisations, as an “intermediate standard” to attain ISO 22000 standard.

SS 590 standard covers any food organization in the food chain which includes, but not limited to activities such as: preparation, processing, manufacturing, packaging, storage, distribution, transportations, handling, supply in any sector of the food chain.

SS 590 is applicable to all food organization which wish to design and implementation of effective food safety management system, regardless of types, sizes, products, and complexity of the organization.

With implementation of SS 590 HACCP based standard, organization practices high food safety and quality standards, which is essential for protection of consumer health and prevent of food borne diseases. In addition, for small and medium-sized enterprise (SMEs) which takes time to comply with ISO 22000 requirements, SS 590 also serves as a foundation for the organization which wish to implement ISO 22000 standard in the future.

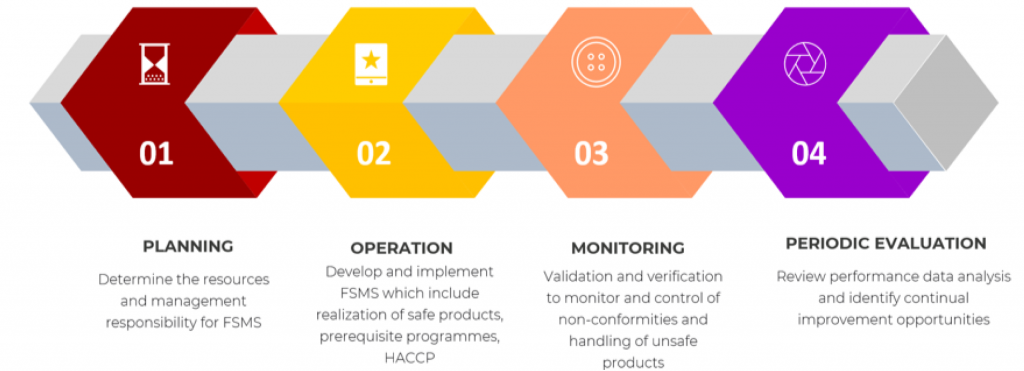

Process Approach

Why is SS 590 certification important?

Organization with SS 590 will demonstrate high assurance on the safety, quality, and integrity of the product/services. SS 590 creates opportunities for an organization for exploration of new market (both locally and globally) besides assisting stronger relationships between suppliers and vendors.

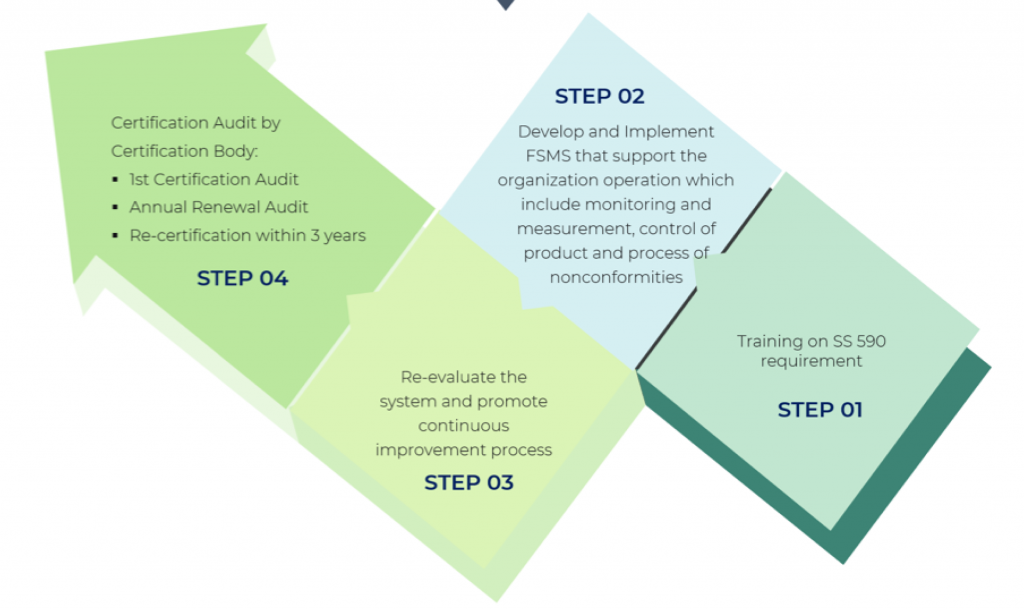

SS 590 Certification Process

Step 1:

People and System Development

Step 1:

People and System Development

Training on SS 590 requirement for relevant personnel within the organization.

Step 2:

System Development and Implementation

Step 2:

System Development and Implementation

Establish a Food Safety Management System that encompass the processes or procedures that support the organization to meet the SS 590 requirements.

Step 3:

Internal Audit and Management Review

Step 3:

Internal Audit and Management Review

Conduct internal audit/review to constantly re-evaluate the system and promote continuous improvement process.

Stage 4:

Certification Audit

Stage 4:

Certification Audit

Certification auditor conduct certification audit (document review and practical application assessment)

Conferral of ISO Certificate

Annual Surveillance Audit

Re-certification within 3 years

Training for SS 590

- SS 590 Awareness Training

- SS 590 Awareness Training

- SS 590 Development and Implementation Training

- SS 590 Development and Implementation Training

- SS 590 Internal Auditor Training

- SS 590 Internal Auditor Training

What does an ISO consultant do?

Our consultants team have vast experience partnering with organizations of all sizes and from all sectors and can provide the resources you need for successful SS 590 certification.

To establish effective Food Safety Management System in your company, our ISO Consultant consider your specific requirements and perspectives and guide your through the process for certification of your Food Safety Management System in accordance with SS 590 requirements following these steps:

Step 1:

Site visit to understand food hazards and business operations.

Site visit to understand food hazards and business operations.

Step 2:

Site consultation & training for development of staff capability on Food Safety Management System.

Site consultation & training for development of staff capability on Food Safety Management System.

Step 3:

Conduct hazard analysis and writing of relevant programme and procedures.

Conduct hazard analysis and writing of relevant programme and procedures.

Step 4:

Advise on monitoring system for each critical control point, corrective actions, validation and verification for HACCP system to improve Food Safety Management System as well as ensure product/services safety.

Advise on monitoring system for each critical control point, corrective actions, validation and verification for HACCP system to improve Food Safety Management System as well as ensure product/services safety.

Step 5:

Support individual departments on their implementation of Food Safety

Management System.

Support individual departments on their implementation of Food Safety

Management System.

Step 6:

Conduct pre-certification audit to verify readiness of your organization for certification.

Conduct pre-certification audit to verify readiness of your organization for certification.

Step 7:

Support during certification and post-certification to close-up any audit findings to ensure smooth and successful certification.

Support during certification and post-certification to close-up any audit findings to ensure smooth and successful certification.