ISO 9001:2015 Quality Management System

ISO 9001:2015 Quality Management System

Meeting clients’ needs is essential in today’s business. ISO 9001:2015 enables an organization to have a quality management system that brings out the confidence in your organization’s ability to provide a product or service that fulfills customer’s needs and expectations.

What is ISO 9001:2015 certification?

ISO 9000 family is the world’s most adopted standard. ISO 9001 sets out the criteria for a Quality Management System and is the only standard in the family that can be certified to. It can be used by any organization, large or small, regardless of its field of activity. In fact, there are over one million companies and organizations in over 170 countries certified to ISO 9001.

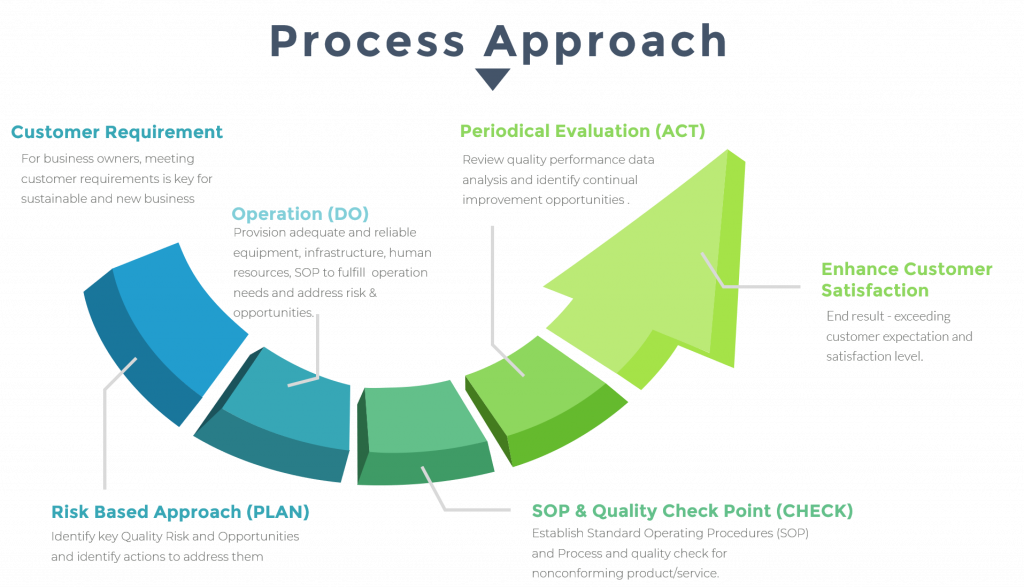

ISO 9001 standard is based on several quality management principles including a strong customer focus, the process approach, the motivation and implication of top management, and continual improvement.

Using ISO 9001 helps ensure that customers get consistent, good quality products and services, which in turn brings many business benefits.

Organizations can be involved in one or more stages of the life cycle, including design and development, operation/production, post-delivery support, and warranty claim. ISO 9001 is applicable to the organization regardless of their size and type.

ISO 9001 focuses on 7 core principles- Customer Focus, Leadership, Engagement with People, Process Approach, Improvement, Evidence-based Decision Making, Relationship Management.

Process Approach

Why is ISO 9001:2015 certification important?

Organizations certified in ISO 9001 show evidence of the ability to consistently provide products and services that meet customer and regulatory requirements. Organization have the competitive edge to access to new market & customer as ISO 9001 certification brings along with customer’s confidence over the product or services.

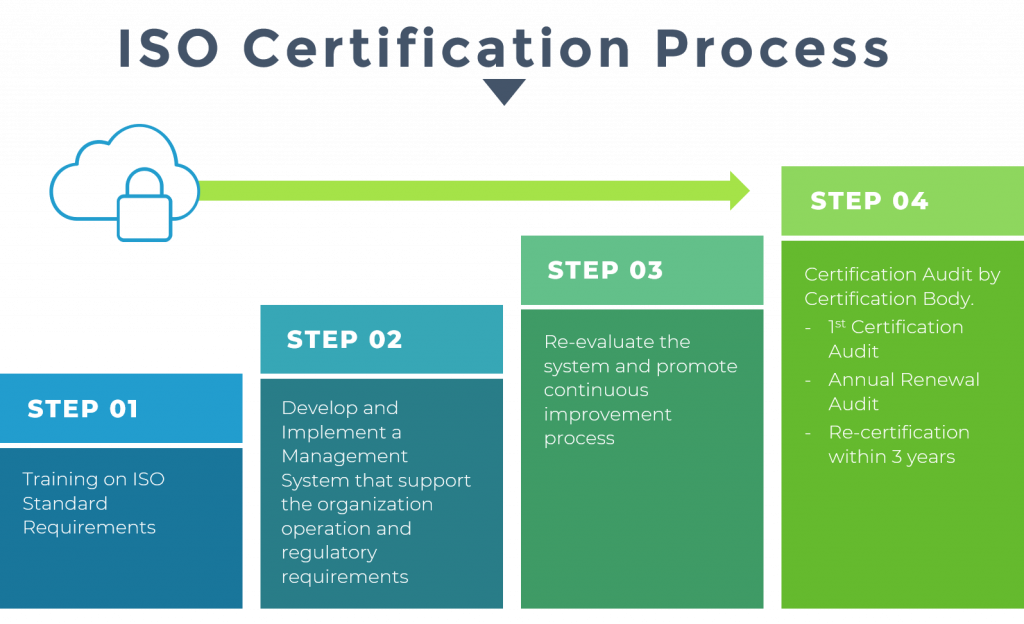

ISO 9001:2015 Certification Process

Step 1:

People Development

Step 1:

People Development

Training on ISO 9001 requirements.

Step 2:

System Development and Implementation

Step 2:

System Development and Implementation

Establish a Quality Management System that encompass the processes or procedures that support the organization to meet the ISO 9001 requirements as well as the client’s expectations.

Step 3:

Internal Audit and Management Review

Step 3:

Internal Audit and Management Review

Conduct internal audits/reviews to constantly re-evaluate the system and promote a continuous improvement process.

Stage 4:

Certification Audit

Stage 4:

Certification Audit

Certification auditor conduct certification audit (document review and practical application assessment)

Conferral of ISO Certificate

Annual Surveillance Audit

Re-certification within 3 years

Training for ISO 9001

- ISO 9001:2015 QMS Awareness Training

- ISO 9001:2015 QMS Awareness Training

- ISO 9001:2015 QMS Development and Implementation Training

- ISO 9001:2015 QMS Development and Implementation Training

- ISO 9001:2015 QMS Internal Auditor Training

- ISO 9001:2015 QMS Internal Auditor Training

What does an ISO consultant do?

Our consultants team have vast experience partnering with organizations of all sizes and from all sectors and can provide the resources you need for successful ISO 9001 certification.

To establish effective quality management in your company, our ISO Consultant considers your specific requirements and perspectives and guide your through the process for certification of your Quality Management System, following these steps:

Step 1:

Site visit to understand your business operations and key quality risk.

Site visit to understand your business operations and key quality risk.

Step 2:

Site consultation & training for the development of staff capability on quality management.

Site consultation & training for the development of staff capability on quality management.

Step 3:

Writing of Quality Management Process and Procedures.

Writing of Quality Management Process and Procedures.

Step 4:

Advice on Key Performance Indicators and analysis to improve product/service performance.

Advice on Key Performance Indicators and analysis to improve product/service performance.

Step 5:

Support individual departments on their implementation of Quality Management System.

Support individual departments on their implementation of Quality Management System.

Step 6:

Conduct pre-certification audit to verify readiness of your organization for certification.

Conduct pre-certification audit to verify readiness of your organization for certification.

Step 7:

Support during certification and post-certification to close-up any audit findings to ensure smooth and successful certification.

Support during certification and post-certification to close-up any audit findings to ensure smooth and successful certification.