FOOD SAFETY

FOOD SAFETY

SS 444:2018 Hazard Analysis and Critical Control Point (HACCP) System

SS 444:2018 Hazard Analysis and Critical Control Point (HACCP) System

HACCP system has gained both national and international endorsement as a cost-effective means for ensuring food safety. The HACCP concept was first developed by the USA in 1960s at National Aeronautics and Space Administration (NASA) to ensure safe food for its astronauts.

Hazard Analysis and Critical Control Point (HACCP) defines the analysis and control of biological, chemical and hazards from raw material production, procurement, and handling process, from manufacturing, to distribution till the consumption of finished product by consumer.

What is SS 444 certification?

SS 444 specifies the requirements for a Hazard Analysis and Critical Control Point (HACCP) food safety management system. HACCP is a tool which use to assess hazards and identify control measures with implementation which mainly focus on the prevention instead of conducting random spot checks on production or conduct laboratory testing of final products.

Hazard Analysis and Critical Control Point (HACCP) specifies hazards and control measures to ensure food safety. It is both scientific and risk based. With HACCP, it enables food establishment and regulatory authorities to identify, prevent and reduce food borne hazards occurs at any segment of the food chain.

There are seven basic principles employed in the development of HACCP – includes hazard analysis, CCP identification, establishing critical limits, monitoring procedures, corrective actions, verification procedures, record keeping and documentation.

The application of the HACCP is the responsibility of each individual business. With implementation of HACCP, it enhances better utilization of resources and promote internal trade by increasing confidence in food safety.

SS 444:2018 is a revision of SS 444:2010. The main change is incorporation of management commitment in the HACCP- based food safety system. A strong commitment to implementation of HACCP by top management gives assurance to employees within the organization the sense of importance of producing safe food.

HACCP Process

Why is SS 444 certification important?

Organizations certified in SS 444 shown evidence ability to efficient control and eliminate food safety hazards and to prevent failure of the food safety practices, which indirectly rescue an organization from loss, or even having to close its doors for good due to food borne diseases which could lead to fatality if severe.

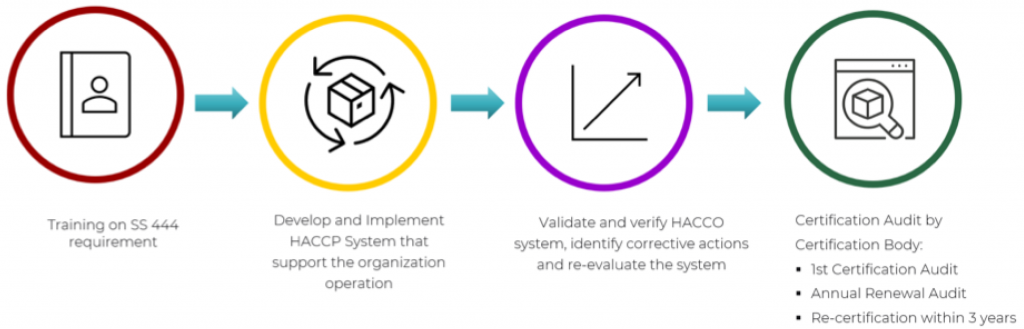

SS 444 Certification Process

Step 1:

People and HACCP System Development

Step 1:

People and HACCP System Development

Training on SS 444 requirement for relevant personnel within the organization

Step 2:

Pre-requisite programme (PRP), Hazard Analysis Plan and Implementation

Step 2:

Pre-requisite programme (PRP), Hazard Analysis Plan and Implementation

Establish pre-requisite programme, conduct Hazard Analysis Plan that encompass each operational process, by determine the Critical Control Points (CCP), critical limit for each CCP with monitoring system in place to meet the SS 444 requirements.

Step 3:

Validation and Verification

Step 3:

Validation and Verification

Conduct internal audit/review to verify HACCP system, identify the necessary corrective actions and constantly re-evaluate the system.

Ensure proper documentation and record keeping in place.

Stage 4:

Certification Audit

Stage 4:

Certification Audit

Certification auditor conduct certification audit (document review and practical application assessment)

Conferral of Certificate

Annual Surveillance Audit

Re-certification within 3 years

Training for SS 444

- SS 444:2018 Awareness Training

- SS 444:2018 Awareness Training

- SS 444:2018 Development and Implementation Training

- SS 444:2018 Development and Implementation Training

- SS 444:2018 Internal Auditor Training

- SS 444:2018 Internal Auditor Training

What does an ISO consultant do?

Our consultants team have vast experience partnering with organizations of all sizes and from all sectors and can provide the resources you need for successful SS 444 certification.

To establish effective HACCP System in your company, our Consultant consider your specific requirements and perspectives and guide your through the process for certification of your developing HACCP System in accordance with SS 444 following these steps:

Step 1:

Site visit to understand food hazards and business operations.

Site visit to understand food hazards and business operations.

Step 2:

Site consultation & training for development of staff capability on HACCP.

Site consultation & training for development of staff capability on HACCP.

Step 3:

Writing of HACCP plan for each operation process .

Writing of HACCP plan for each operation process .

Step 4:

Advise on monitoring system for each critical control point, corrective actions, validation and verification for HACCP system.

Advise on monitoring system for each critical control point, corrective actions, validation and verification for HACCP system.

Step 5:

Support individual departments on their implementation of documentation and record keeping.

Support individual departments on their implementation of documentation and record keeping.

Step 6:

Conduct pre-certification audit to verify readiness of your organization for certification.

Conduct pre-certification audit to verify readiness of your organization for certification.

Step 7:

Support during certification and post-certification to close-up any audit findings to ensure smooth and successful certification.

Support during certification and post-certification to close-up any audit findings to ensure smooth and successful certification.