FOOD SAFETY

FOOD SAFETY

Food Safety System Certification 22000

(FSSC 22000)

Food Safety System Certification 22000

(FSSC 22000)

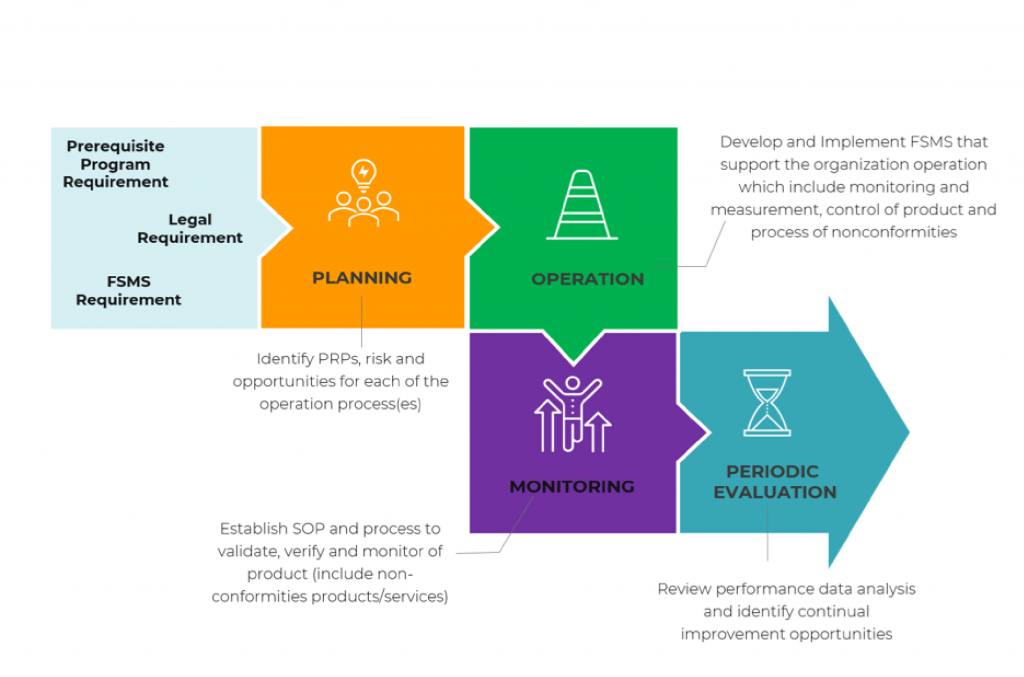

Food Safety System Certification 22000 (FSSC 22000) offers a complete certification Scheme for auditing and certification for Food Safety Management System (FSMS) or FSMS and Quality Management Systems (FSSC 22000-Quality). FSSC 22000 consists of 3 components: ISO 22000, sector-specific PRPs and additional requirements.

What is FSSC 22000 certification?

FSSC 22000 is a Food Safety System Certification Scheme, managed by Foundation FSC 22000, which used to control food safety risks.

FSSC covers processing, manufacture and handling wide range of foods to manage food safety risks for provision of safety products to consumers and use by companies in the food industry. For example, FSSC has been developed to include food industry companies, processors of animal and plant respective food industry, food ingredients producers include food additives, bio-culture drinks.

Besides, FSSC 22000 does extend to transport and storage industries where their part of work performed by the organisation producing/processing in food industry. Recently, Carry Transit, the food-grade division of Superior Bulk Logistics, was the world’s first food-grade motor carrier to attain FSSC 22000 for Transport and Storage across all its 39 U.S. terminals and railyards.

FSSC 22000 is recognised by Global Food Safety Initiative (GFSI). FSSC 22000 allows building in confidence within customers in organisation food safety program, which indirectly assist the organisation to explore global markets. FSSC 22000 uses a management system approach to food safety, using ISO 22000 for the management system requirement and ISO Technical Standards (for prerequisite program requirements). FSSC 22000 integrates well with management systems such as ISO 9001 and ISO 14001.

With FSSC 22000, it enables establishment of an effective food safety management system which continually manage, monitor, validate and improve the operational process, which lead to an effective management of food safety hazards. In addition, it opens a large market for the organization as large retailers and manufacturers/processors often look for organization with FSSC for their suppliers.

Process Approach

Why is FSSC 22000 certification important?

Why is FSSC 22000 certification important?

Organizations certified in FSSC 22000 showed ability to have good governance with multiple stakeholder approach in development of food safety management system. Organization with FSSC 22000 practice optimized communication in the food supply chain beside compliance with relevant legislation and regulations, leading organization to international food industry acceptance.

FSSC Certification Process

Step 1:

People and System Development

Step 1:

People and System Development

Training on FSSC 22000 requirement for relevant personnel within the organization.

Step 2:

System Development and Implementation

Step 2:

System Development and Implementation

Establish an ISO 22000 Food Safety Management System that encompass the processes or procedures that support the organization to meet the FSSC 22000 requirements.

Step 3:

Internal Audit and Management Review

Step 3:

Internal Audit and Management Review

Conduct internal audit/review to constantly re-evaluate the system and promote continuous improvement process.

Stage 4:

Certification Audit

Stage 4:

Certification Audit

Certification auditor conduct certification audit (document review and practical application assessment)

Conferral of

ISO Certificate

Annual Surveillance Audit

Re-certification

within 3 years

ISO Certificate

within 3 years

Training for FSSC 22000

- FSSC 22000 Awareness Training

- FSSC 22000 Awareness Training

- FSSC 22000 Development and Implementation Training

- FSSC 22000 Development and Implementation Training

- FSSC 22000 Internal Auditor Training

- FSSC 22000 Internal Auditor Training

What does an ISO consultant do?

Our consultants team have vast experience partnering with organizations of all sizes and from all sectors and can provide the resources you need for successful FSSC 22000 certifications.

To establish effective FSSC 22000 in your company, our ISO Consultant consider your specific requirements and perspectives and guide your through the process for certification of your Food Safety Management System in accordance with FSSC 22000 requirement following these steps:

Step 1:

Site visit to understand your business operations, key hazards, risks, opportunities,

prerequisite program requirements and additional requirements for each operational process.

Site visit to understand your business operations, key hazards, risks, opportunities,

prerequisite program requirements and additional requirements for each operational process.

Step 2:

Site consultation & training for development of staff capability on Food Safety Management System.

Site consultation & training for development of staff capability on Food Safety Management System.

Step 3:

Writing of prerequisite program requirements, procedures, and hazard analysis for each operation processes.

Writing of prerequisite program requirements, procedures, and hazard analysis for each operation processes.

Step 4:

Advise on Key Performance Indicators and analysis to improve Food Safety Management System as well as ensure product/services safety.

Advise on Key Performance Indicators and analysis to improve Food Safety Management System as well as ensure product/services safety.

Step 5:

Support individual departments on their implementation of Food Safety Management System.

Support individual departments on their implementation of Food Safety Management System.

Step 6:

Conduct pre-certification audit to verify readiness of your organization for certification.

Conduct pre-certification audit to verify readiness of your organization for certification.

Step 7:

Support during certification and post-certification to close-up any audit findings to ensure smooth and successful certification.

Support during certification and post-certification to close-up any audit findings to ensure smooth and successful certification.