FOOD SAFETY

FOOD SAFETY

ISO 22000:2018 Integrated Food Safety Management System

ISO 22000:2018 Integrated Food Safety Management System

Safety in the food industry mainly consist of two interfaces:

(1) between industry and the market- which mainly concerned on the origins of raw materials, chemicals and pesticide level, food hygiene, food labelling and food storage;

(2) between market and the consumer- which particularly need to make sure the food handling, food preparation and food storage are safe.

However, there remains overlapping parts in the two interface which is our food defence. The key is to prevent food borne illness being passed to the final consumers.

(1) between industry and the market- which mainly concerned on the origins of raw materials, chemicals and pesticide level, food hygiene, food labelling and food storage;

(2) between market and the consumer- which particularly need to make sure the food handling, food preparation and food storage are safe.

What is ISO 22000 certification?

ISO 22000 specifies requirements for a food safety management system. It maps out what an organization needs to do to demonstrate its ability to control food safety hazards to ensure food is safe.

All food producers can adopt ISO 22000, regardless their sizes and type of products, as they have responsibilities to ensure the products are safe- from farm to table, besides building the trust and confidence level of consumers.

ISO 22000 can be used with ISO 9001 to develop a management system that address both food safety and quality issues. Organizations can make decision to determine the extent of integration between the two management systems (e.g. development of two separate systems that share common processes or a single fully integrated management system) based on the organization culture and operations that support the development and implementation of management systems.

Besides seven core principles of ISO management standards (i.e. customer focus, leadership, engagement of people, process approach, improvement, evidence-based decision making and relationship management), ISO 22000 also focus on four key elements – interactive communications, system management, prerequisite programmes, hazard analysis and crucial control point (HACCP) principles.

With ISO 22000, it provides a layer of reassurance within the food supply chain, in addition to assist products to import and export between nations and borders and providing people food they can trust.

Why is ISO 22000 certification important?

Why is ISO 22000 certification important?

Organizations certified in ISO 22000 shown evidence ability to efficient control and eliminate food safety risks, which build in confidence among stakeholders and suppliers within the food supply chain. With ISO 22000, it provides organization with superior food safety and security, to prevent failure of the food safety practices, which indirectly rescue an organization from loss, or even having to close its doors for good due to food borne diseases which could lead to fatality if severe.

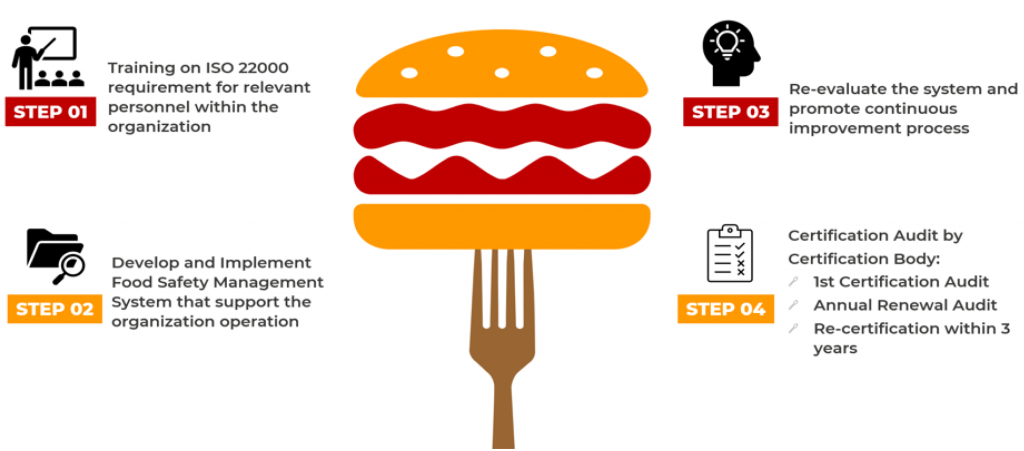

ISO 22000 Certification Process

Step 1:

People and System Development

Step 1:

People and System Development

Training on ISO 22000 requirement for relevant personnel within the organization.

Step 2:

System Development and Implementation

Step 2:

System Development and Implementation

Establish a Food Safety Management System that encompass the processes or procedures that support the organization to meet the ISO 22000 requirements.

Step 3:

Internal Audit and Management Review

Step 3:

Internal Audit and Management Review

Conduct internal audit/review to constantly re-evaluate the system and promote continuous improvement process.

Stage 4:

Certification Audit

Stage 4:

Certification Audit

Certification auditor conduct certification audit (document review and practical application assessment)

Conferral of ISO Certificate

Annual Surveillance Audit

Re-certification within 3 years

Conferral of ISO Certificate

Annual Surveillance Audit

Re-certification within 3 years

Training for ISO 22000

- ISO 22000:2018 Awareness Training

- ISO 22000:2018 Awareness Training

- ISO 22000:2018 Development and Implementation Training

- ISO 22000:2018 Development and Implementation Training

- ISO 22000:2018 Internal Auditor Training

- ISO 22000:2018 Internal Auditor Training

What does an ISO consultant do?

Our consultants team have vast experience partnering with organizations of all sizes and from all sectors and can provide the resources you need for successful ISO 22000 certification.

To establish effective Food Safety Management System in your company, our ISO Consultant consider your specific requirements and perspectives and guide your through the process for certification of your Food Safety Management System in accordance with ISO 22000 requirements following these steps:

Step 1:

Site visit to understand your business operations and key hazards, risks and opportunities for each operational process.

Site visit to understand your business operations and key hazards, risks and opportunities for each operational process.

Step 2:

Site consultation & training for development of staff capability on Food Safety Management System.

Site consultation & training for development of staff capability on Food Safety Management System.

Step 3:

Writing of Procedures and conduct hazard analysis for each operation process.

Writing of Procedures and conduct hazard analysis for each operation process.

Step 4:

Advise on Key Performance Indicators and analysis to improve Food Safety Management System as well as ensure product/services safety.

Advise on Key Performance Indicators and analysis to improve Food Safety Management System as well as ensure product/services safety.

Step 5:

Support individual departments on their implementation of Food Safety Management System.

Support individual departments on their implementation of Food Safety Management System.

Step 6:

Conduct pre-certification audit to verify readiness of your organization for certification.

Conduct pre-certification audit to verify readiness of your organization for certification.

Step 7:

Support during certification and post-certification to close-up any audit findings to ensure smooth and successful certification.

Support during certification and post-certification to close-up any audit findings to ensure smooth and successful certification.